In-House Manufacturing Done Right: Why Paragon Pro Is Built for Builders

Share

Tired of Playing Middleman Between Vendors?

Let’s be honest, chasing parts, tracking timelines, and holding every vendor accountable gets old fast. If you’re building a product that’s meant to last, you shouldn’t have to spend your days babysitting the supply chain.

That’s why we built Paragon Pro to be different. We’re not some pass-through job shop. We’re a full-service manufacturing partner that takes the whole process off your plate. You bring the vision. We build it.

What We Handle In-House (So You Don’t Have To)

When we say “in-house”, we mean it. We will handle all the small details so you don’t have to. We trust our people, most have worked with us for years, so you don’t have to deal with any surprises.

Here’s what that looks like in real life:

-

Raw Material Sourcing

Whether it's steel, aluminum, or custom specs, we’ve got reliable sourcing nailed down. -

Laser Cutting, Machining & Bending

Precision? You bet. From intricate custom shapes to high-volume jobs, we get it right, the first time. -

Punch Presses & Hydraulic Forming

Heavy-duty forming that hits hard, holds strong, and keeps tolerances tighter than your timeline. -

Certified Welding

No guesswork here. Our welders are certified pros who know their way around every kind of joint and alloy. -

Full Assembly & Testing

We don’t just ship parts. We build finished, tested products that are ready to roll. No surprises. -

Industrial Painting & Coating

Your product won’t just work, it’ll look sharp and stand up to the elements too. -

Packaging, Palletizing & Drop Shipping

Ready for retail? B2B shipping? Amazon fulfillment? We’ll wrap it, pack it, and ship it where you want it. -

Optional Sales Support

Want some added visibility? We can even feature your product on our website. Just say the word.

Real Control. Real Flexibility. Real Fast.

Here’s the thing: in-house = in control. You’re not stuck waiting on third-party updates, overseas delays, or mystery quality issues. You know where your product is. You know who’s working on it. And you know it’s going to show up right.

Need to make a last-minute change? We can pivot. Want to scale up a run? No problem. We’re fast because we’re flexible. That’s only possible when it’s all done under one roof.

Built for the Builders

We know who you are. You’re not just sitting in a cubicle drawing concepts. You’re on the floor. On the phone. In the grind. You’re sweating the details because you give a damn about the end result.

That’s who we built Paragon Pro for.

Guys who want real support. Real tools. Real output. Whether you're building an electric off-road beast, a badass lifting rig, or the next generation of smart shop equipment—we're here to make it happen.

Why Our Customers Stay With Us

Let’s break it down. Our clients stick with us because:

✅ We keep deadlines.

✅ We know what we’re doing.

✅ We don’t cut corners.

✅ We get things out the door, done right.

You're not just another line item—we actually care if your product succeeds. Because when your gear works, and your brand grows, we both win.

How We Make Your Life Easier

Bringing your manufacturing closer to home means more than just faster shipping. It means:

- Less time chasing vendors

- Fewer quality control headaches

- Easier communication (no 3 a.m. calls to China)

- More confidence in your product

- Faster iterations and product improvements

- A U.S.-based team that has your back

Real Talk: Job Shops vs. Full-Service Partners

There’s nothing wrong with a shop that just cuts metal. But if you’re trying to scale, improve, and dominate your category you need more than that.

You need:

- A team that sees the big picture

- A partner that can take a napkin sketch to a finished unit

- A setup that grows with you - not one that holds you back

That’s the difference between a typical shop and Paragon Pro.

FAQs: You Ask, We Answer

Q: Can I send you my own raw materials?

A: Yep. We’re flexible like that. But we can also source exactly what you need usually faster costs a lot less.

Q: Can I just use you for one part of the process?

A: Sure. But once you see how smooth it is having us do it all… you’ll probably stick around.

Q: Are you just for big runs?

A: Nope. We do short runs, prototyping, and full-scale production. We grow with you.

Q: Will you work with my design team?

A: Absolutely. We love collaborating. From engineering, CAD, testing, you name it.

Ready to Build Something Real?

If you’re done juggling vendors and chasing missed deadlines, it’s time to bring it all home. Paragon Pro has the tools, the team, and the drive to build what you’ve got in mind. From start to finish.

✅ Raw materials? Check.

✅ Precision fabrication? Check.

✅ Coating, assembly, and shipping? Yep.

✅ Peace of mind? You bet.

So, if you’re ready to move fast, build smart, and get your product out the door, take a minute to fill out the contact form.

📦 Paragon Pro. Manufacturing Solutions.

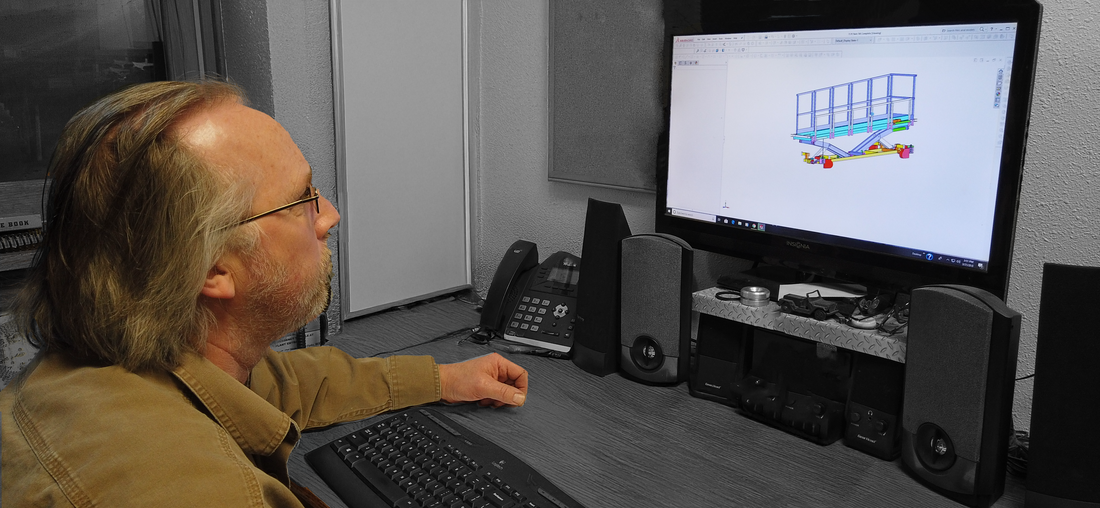

This is a product that we custom designed to serve a global customer for use in installing elevator canopies in new construction, maintenance and renovation. This was a take-off from some of the design elements in our hydraulic Model 460 PANELLIFT® Drywall Lift. We added a couple of patent pending features as we arrived at this solution for a real safety and ergonomics problem for one of our customers.

- 600 lbs. load capacity

- Max reach 9'

- Push button, battery and hydraulic powered

- Made in USA

- Can rotate to 15 degrees for vertical entry through door opening

- Unique tilt mechanism provides complete control while positioning canopy assemblies